You also need to specify the type of emulsion your using as they all have varying exposure times. Your screen print supply vendor should have them. Show us your work! Be proud of what you do, showing off your work could easily influence and inspire others! Be warned: pics are fine, but if it's too "spammy" your post will be removed. Its best to get yourself an exposure calculator. Share knowledge! Every screen printer does things a little differently share your techniques However, there's nothing wrong with general discussion.Īny links to videos, articles, websites, et. Hey I'm new to this, what type of ink do you guys suggest I start with and what are the differences in types of inks?

Please refrain from posts that ask across-the-board questions.

#EXPOSURE TIME FOR 160 MESH SCRFEEN SPEEDBALL EMULSION REGISTRATION#

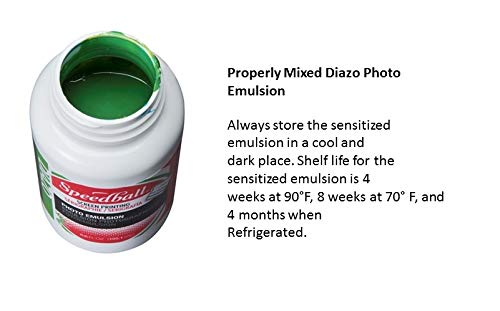

No matter what your skill level, whether you are a beginner who can't register a single image to a blank sheet of paper or a print god who yawns and lays down a four-color halftone perfectly with no hinge clamps or registration marks, there are ALWAYS questions. Visit the fine-art screen printing sub-reddit: /r/serigraphy We welcome most posts, typically: questions, interesting links, tips&tricks, etc. For best results it should only be stored in its original container.This is a subreddit specifically devoted to the art and crafts of serigraphy(screen printing). If youre doing silkscreen printing using a direct photo emulsion such as Speedball Diazo Screen Printing Photo Emulsion, you can use sunlight instead of the. It should not be stored at temperatures above 80f (27c) or below 37f (0c). Shelf Life - Approximate shelf life for this emulsion is 24 month (2 years) when stored at room temperature. This will cause premature stencil breakdown and poor ink deposit. thickness will decrease and go thinner on the print side. If the coating ends on the print side, the E.O.M. Finish the last coating on the squeegee side. It is not recommended to finish the last coating on the print side of the screen. Remember, these exposure settings should only be used as a guide since exposure time will vary depending on equipment used, lamp life, type of emulsion, and applied coatings. On mesh counts of 300 to 350 allow 50 to 60 seconds exposure, and for mesh counts of 350 or more allow 30 to 45 seconds for exposure. When using a 3KW Metal Halide Exposure lamp on mesh counts from 80 to 300 as a guide, set your exposure time between 160-200 seconds. Procoat will work well with mesh counts of 74 or higher. Excellent for all type of plastisol applications. Its best to get yourself an exposure calculator. Red-pink in color, this photopolymer emulsion offers 42% sensitized solids and 6000 CPS sensitized viscosity. Procoat is a fast exposing emulsion so care should be taken during handling to avoid exposure to daylight, quartz/halogen lamps, cool white fluorescent lamps, or discharge lamps. It is 42% solids and presensitized so that pre-mixing sensitizer is not required. It can also be used with water-based ink systems, however post exposing is required. Texsource Procoat is an economical red/pink photopolymer emulsion designed for textile printers using plastisol and post exposed water-based inks. Texsource is not responsible for items damaged by exposure to extreme temperatures. IMPORTANT : Texsource ships in-stock items as orders are placed, and cannot guarantee that temperature-sensitive items, like emulsions and emulsion removers, will not be exposed to freezing temperatures in transit.

0 kommentar(er)

0 kommentar(er)